ZLD Projects

- Home

- PERTEC

We are pleased to share the latest updates on the PERTEC IFLDP-STEP Scheme Project, which aims to achieve Zero Waste Discharge and upgrade the Common Effluent Treatment Plant (CETP) as part of our ongoing commitment to sustainable environmental solutions.

The project has been sanctioned and is progressing smoothly in accordance with the planned schedule.

As part of the initiative:

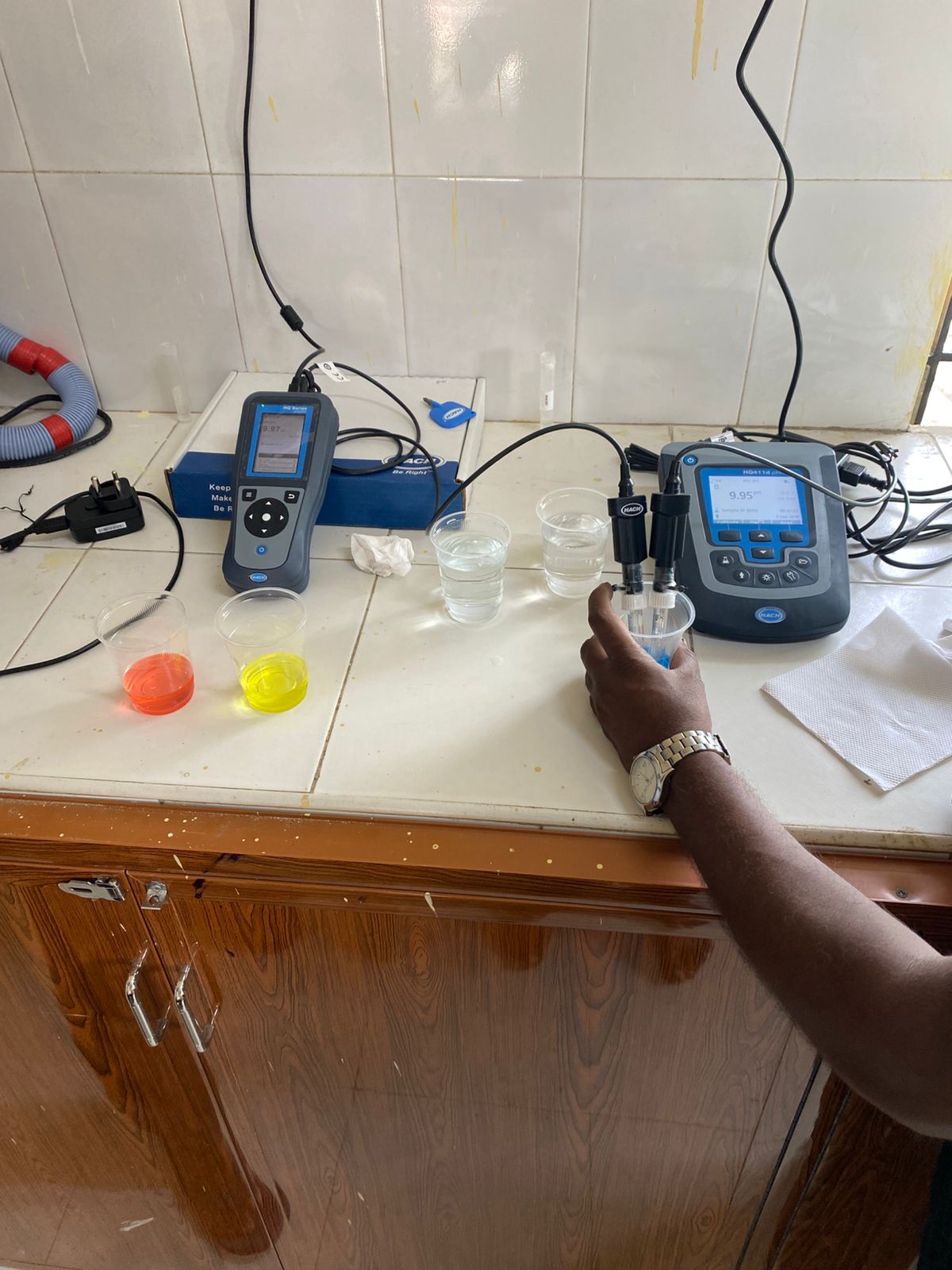

Tender P4, focused on the upgradation of the laboratory, has been successfully completed, ensuring advanced analytical capabilities for environmental monitoring.

Tender P2, involving the scientific closure of the existing Secured Landfill (SLF) over an area of 4000 m², is currently underway and progressing as per schedule.

TALCO PERNAMBUT TANNERY EFFLUENT TREATMENT COMPANY LIMITED

Pernambut town, situated in Vellore district, 50 km from Vellore, is one of the main and oldest centres for leather processing industry. There are 36 tanneries presently functioning in this tannery cluster, in two sectors, namely Bakkalapalli and V.Kota Road sectors. Tanneries in this cluster mainly processes vegetable tanned sole leather from raw to wetblue and semi finished to finished.

TALCO Pernambut Tannery Effluent Treatment Company Limited (PERTEC) conceived two CETPs for the then operating and proposed tanneries. The Bakkalapalli sector CETP served 19 tanneries another for V.Kota Road sector to serve 18 tanneries. Subsequently Bakkalapalli CETP alone could be completed for a capacity of 900 m3/d and 19 tanneries connected to this CETP are functioning with all necessary treatment measures. At present there are 18 tanneries are operating with their own individual effluent treatment plants. All these units, 18 from Bakkalappally sector and another 18 from V Kota sector were made part of the ZLD system proposed for this CETP.

The CETP, by name Pertec is managed by a company registered under the Indian Companies Act and managed by a BoD, drawn from its members. ShriP. Md. Basha, a prominent tanner of the area, is currently the Managing Director of the company.

Contact details of the CETP:

Talco Pernambut Tannery Effluent Treatment Co. Ltd

Bakkalapalli Sector, # 299/A, High Road ,

Pernambut – 635 810.

Telephone : +91-4171-233 093 / 232 584 / 232 245

Fax : +91-4171-230 659 / 232 584.

Email : tannersassn_pbt@yahoo.co.in

Contact Person : Mr. P. Md. Basha, Managing Director, Mob: 94861 74449

Project Components

The ZLD system proposed in Pertec CETP consisted of the following:

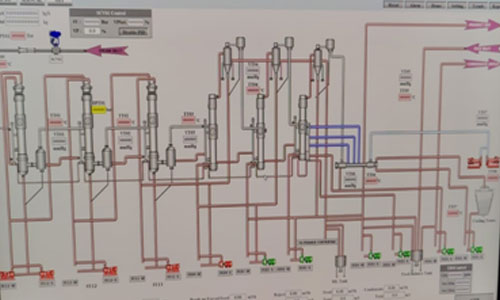

- CETP upgradation: new mechanical screen, pre-settler, modification of equalisation tank with new mixing system, new mechanisms and bridges for primary & secondary clarifiers, additional mechanical sludge dewatering, new aeration system complete with civil works, blower and diffusers, softening to remove hardness and improvement in monitoring.

- RO system: Pre-treatment filtration, organic scavenger, ultra-filtration, two stage reverse osmosis and automated control system for the same.

- Mechanical Evaporation of RO reject: Five effect evaporation with thermal vapour re-compression system and pusher centrifuge for separation of salts.

- Recovered water conveyance system: overhead tanks and piping system with metering for conveying the recovered water back to individual tanneries. Individual tanneries to provide storage tanks with more than one day storage capacity within their premises.

The turnkey implementation of the project was awarded to Hyderabad based Ramky Infrastructure Ltd based on a two stage competitive tendering. The contract value is Rs. 19.89 crores and the total project cost including administrative charges is Rs. 20.88 Crores.

After handing over of the Zero Liquid Discharge system to PERTEC CETP

Upgradation of ZLD system in PERTEC CETP

In 2018, SIDCO-II CETP had submitted a proposal to DPIIT for upgradation of the ZLD system and reduction of O&M cost under the IFLADP Scheme. The following components were approved with 70% funding by DPIIT and balance to be equally shared by the Industries Department of the Government of Tamil Nadu and the beneficiary CETP.

Given below is a table showing the details of the components being upgraded under the above project and the status as on 12 April 2022:

| # | Name of the item as per the DPIIT sanction | Sanctioned cost | Physical status of each component in % |

|---|---|---|---|

| B2 | Up-gradation of PST treatment – Equalization Tank | 127.58 | 100% |

| B3 | Filter Press 4 t/d | 84.51 | 100% |

| C4 | Pretreatment to RO (Pelletizer) | 50.8 | 85% |

| C5 | 2 stage R O plant 400 m3/day including HPRO -320 m3/d | 392.73 | 75% |

| D6 | MEE -200 KLD | 739.29 | 80% |

| E7 | Solar Power (1MW) | 450 | 80% |

| TOTAL PROJECT COST | 1844.91 |