ZLD Projects

- Home

- DINTEC

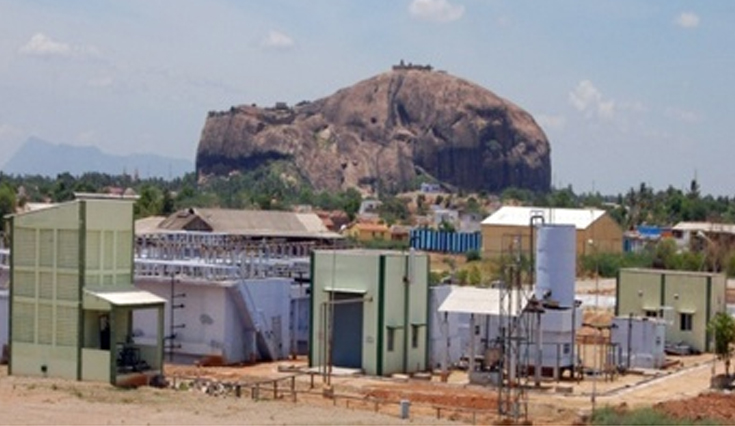

CEMCOT-DINTEC CETP Project at Dindigul

The Common Effluent Treatment Plant (CETP) under the management of M/s.TalcoDindigul Tanners Enviro Control Systems (P) Ltd. was established for a capacity of about 2500m3/day. Currently 49 tanneries are connected to the CETP. Though these units have provision to adopt all types of tanning, at present they adopt the traditional vegetable tanning process to suit market demand.

DINTEC ZLD project was approved with other projects of CEMCOT in February 2009. But its implementation was deferred as the DINTEC CETP was hoping to get state government’s approval to its proposal to dilute its treated effluent with treated domestic sewage as a mode of its disposal. As this process was taking an inordinately long time, to avoid punitive action by the TNPCB, the CETP management decided to go ahead with the ZLD project. As there had been considerable delay of more than a year, as per the directions of DIPP, Govt. of India, the CEMCOT-DINTEC CETP up gradation project was retendered for a total value of Rs.35,45,39,880/- The approved total project cost inclusive of the overhead charges etc., worked out to Rs.37,22,66,874/-. The project was started in March, 2012.

The Common Effluent Treatment Plant (CETP) under the management of M/s.TalcoDindigul Tanners Enviro Control Systems (P) Ltd. was established for a capacity of about 2500m3/day. Currently 49 tanneries are connected to the CETP. Though these units have provision to adopt all types of tanning, at present they adopt the traditional vegetable tanning process to suit market demand.

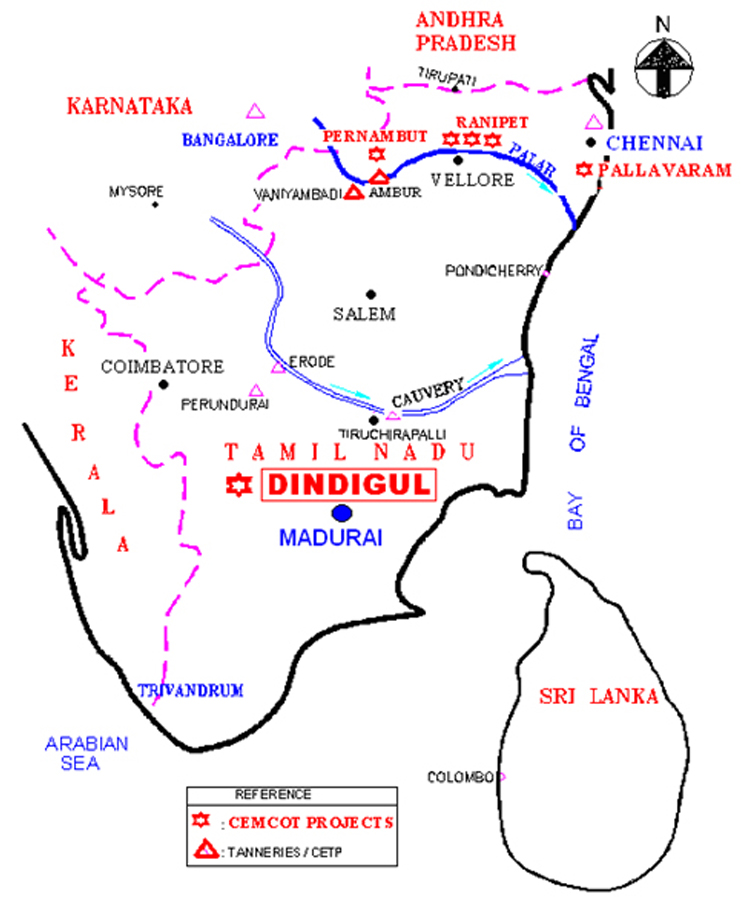

Location of DINTEC - CETP, Dindigul, Madurai

Contact details of the CETP :

Talco Dindigul Tanners Enviro Control System Pvt Ltd

Batlagundu Bypass Road, Begambur (PO),

Dindigul – 624 002.

Telephone: +91-451-2401 834 / 2401 028

Email : dintecpltd@yahoo.co.in

Contact person : Shri A. Mohideen, Managing Director

Major components of ZLD system

The ZLD system proposed in Dindigul CETP (DINTEC) consisted of the following:

- 1. New pre-treatment units in 49 individual units

- 2. New HDPE pipelines & improved pumping system

- 3. Up-gradation of CETP and sludge management system

- 4. UF/RO System in new building

- 5. Utilisation of treated effluent

- 6. Mechanical evaporator and residual saline water & sludge management

Status of the project

CETP UPGRADATION

- 1. Improved pre-treatment in 49 individual units have been completed and are in operation.

- 2. New 26km HDPE pipelines & improved pumping system from tanneries to CETP – Laying of pipes were completed and the system is in regular uses.

- 3. Up-graded CETP - Civil works for pre-settler, primary clarifier and aeration tank completed. Equipments supplied and erected. The system is under regular operation.

UF/RO System

Two modules of UF/RO and third stage RO units had been erected and are under operation.

Multiple Effect Evaporation system

Evaporation system and residual saline water & sludge management – All the equipment, interconnecting pipes pumps etc. were supplied, erected and the system had been tested on trial basis which achieved its object, producing salt.

Salt Storage and Recovered water distribution system

All equipment and civil works have been supplied/erected and are under operation

The project has been successfully commissioned and handed over to the CETP in November 2017 and is in regular operation since then

Ongoing upgradation of ZLD projects at a glance

| # | Name of the Project | Approved cost in Rs. Crore | Share of GoI, GoTN and beneficiary CETP | ||

|---|---|---|---|---|---|

| GoI | GoTN | CETP | |||

| 1 | Upgradation of ZLD system in RANITEC CETP | 85.07 | 59.54 | 12.76 | 12.76 |

| 2 | Upgradation of ZLD system in SIDCO-I CETP | 42.41 | 29.69 | 6.36 | 6.36 |

| 3 | Upgradation of ZLD system in SIDCO-II CETP | 21.38 | 14.97 | 3.20 | 3.20 |

| 4 | Upgradation of ZLD system in PERTEC CETP | 19.17 | 13.42 | 2.88 | 2.88 |

| TOTAL | 168.03 | 117.62 | 25.20 | 25.20 | |